During the peak of the COVID-19 pandemic, automation proved to be an essential aspect of manufacturing. Many companies were… Read more »

Category: Videos

See the FlexMove Stop and Divert Modules in Action

Dorner’s FlexMove Puck Stop Module and a Puck/Package Divert Module give users the ability to stop pucks or packages for pacing requirements,… Read more »

Learn How to Service Your ERT250 Conveyor

ERT250 Conveyors Dorner’s ERT250 Conveyor is the latest advancement in pallet and tray handling conveyance. This new type of… Read more »

Center Top Guide Provides Lane Control on FlexMove Conveyor

Dorner Asia recently worked with an automotive machine maker in Malaysia to integrate a conveyor with a robot for… Read more »

Find the Perfect Fit with Miniature Conveyors

Are you looking for a conveyor to move small or lightweight product? Do you need a conveyor to designed for… Read more »

Design Your Own Conveyor Online

Dorner’s DTools: the industry leading tool for online conveyor design! DTools is the central location for all of Dorner’s… Read more »

55 Years of Passion & Innovation

Since 1966 Dorner has evolved from a small tool and die shop to the global conveyor manufacturer of today.… Read more »

Retractable Tail Provides Simple Walk-Through Access

Space can be limited on the factory floor and equipment isn’t always easy to access. Conveyors and other machinery… Read more »

Is an Alpine Conveyor Right for Your Application?

In most facilities, space is a premium, and conveyor location is often dependent on machinery and facility design. Dorner’s Alpine… Read more »

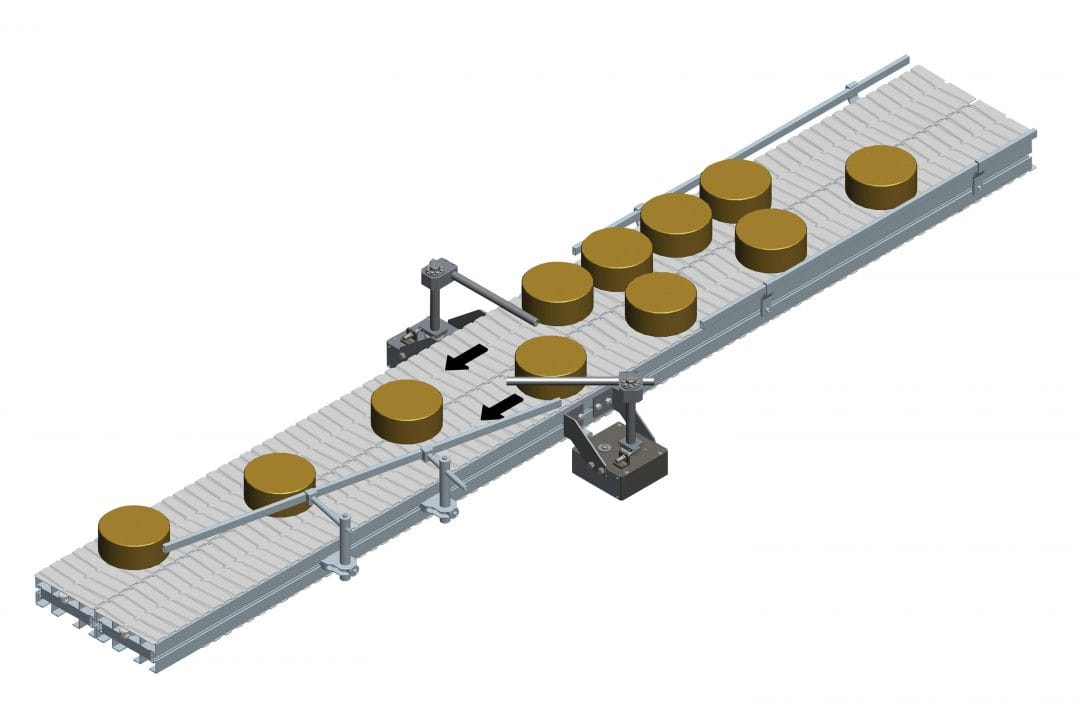

Merging and Laning System for Sauce Packaging

Often during the packaging process, product needs to be either merged or separated into separate lanes as it moves… Read more »

How to Service Your AquaGard 7350 Belted Conveyor

The AquaGard 7350 Series is Dorner’s go to conveyor for wipe down and low pressure wash-down sanitary applications. They… Read more »

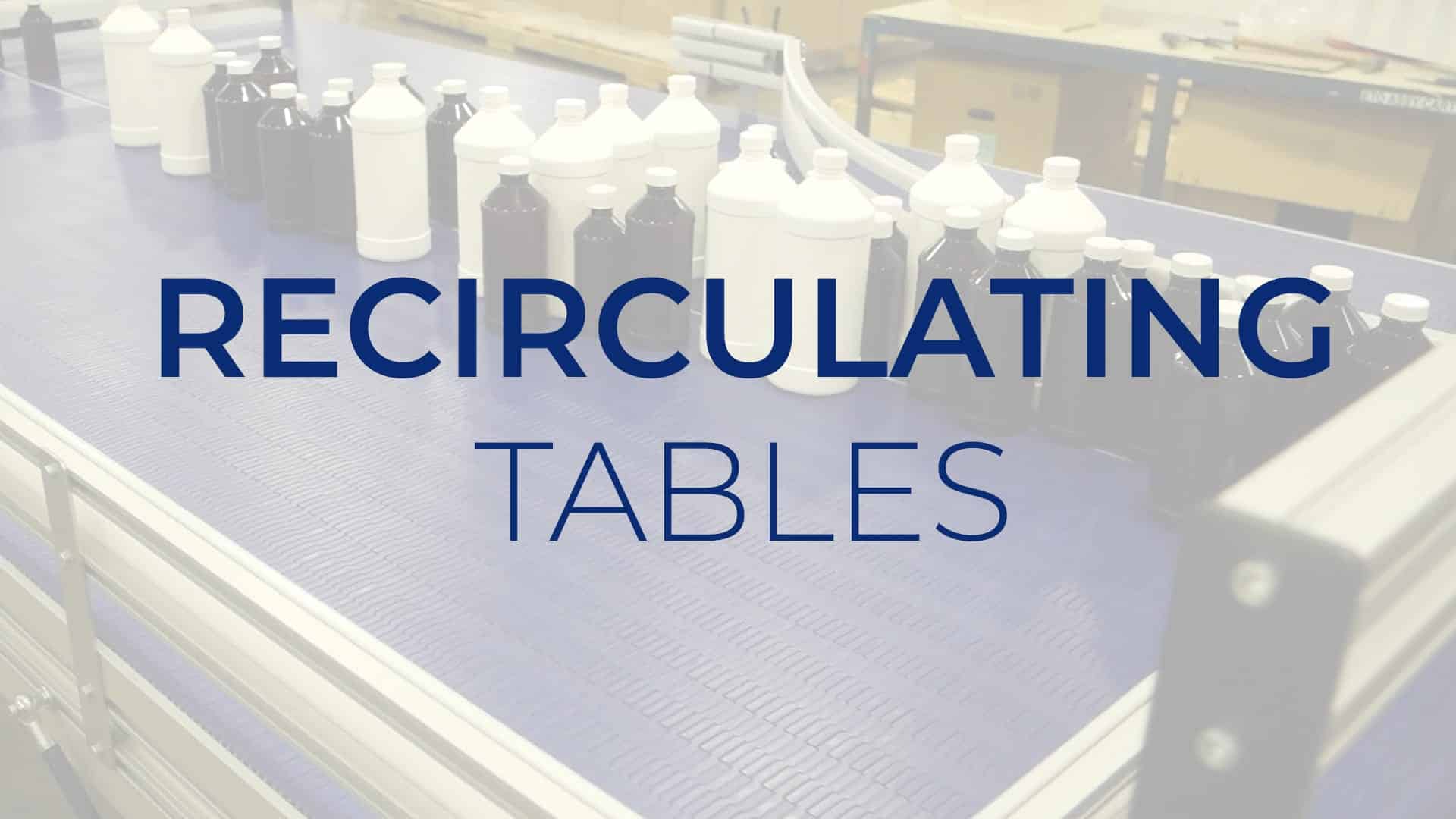

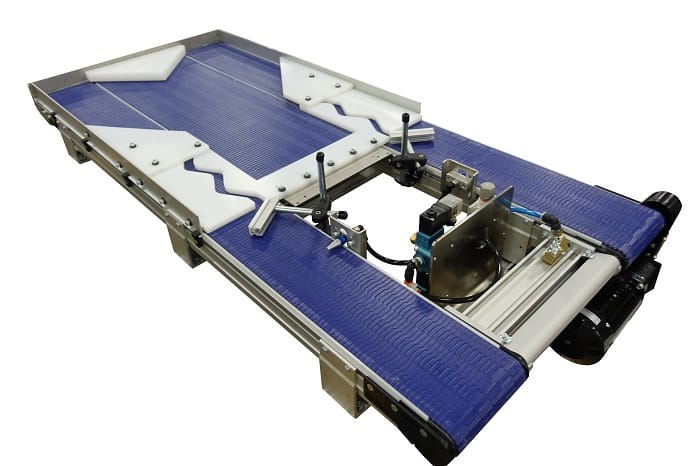

5 Important Facts About Dorner’s Recirculating Tables

See our recirculating tables in action at the end of the post! 1. They enable product lines to keep pace… Read more »

Create Safe and Fast Walk-Through with Lift Gates

Lift gate conveyors are a popular solution for creating safe and fast walk-through access to maximize usable space. Take… Read more »

How do Diverting and Sorting Conveyors Work? Take a Look.

Conveyor diverters and sorting conveyors work by handling product based on such characteristics as weight and shape along with line… Read more »

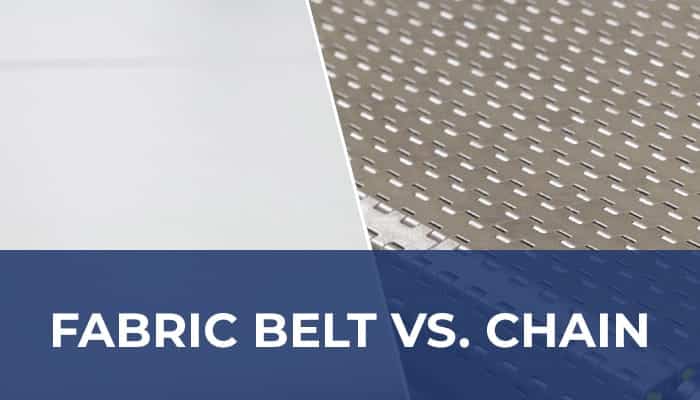

Watch Now: Choosing the Right Belt – Fabric Belt or Chain

One of the first considerations when choosing a conveyor is the belt. How do you know which type of… Read more »

Add Simple Automation with Retractable Conveyors

A retractable conveyor, or retracting tail, is a conveyor frame with the ability to retract or extend, typically on… Read more »

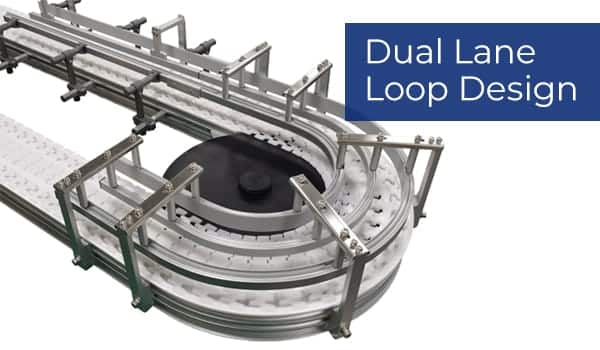

Merge Product Smoothly from Two Lanes into One

The new FlexMove Side Acting Merge Module from Dorner is a fully mechanical design to simply and easily merge products… Read more »

See the New ERT250 in Action!

Dorner’s new ERT250 Conveyors utilize Edge Roller Technology to provide low back pressure accumulation, non-contact zoning, and conventional transport, all… Read more »

Get Started with Conveyor Basics

What is a conveyor? Are you interested in learning more about conveyors, but don’t know where to start? Take… Read more »

Learn the Service Basics For Your 3200 Series Center Drive

Dorner’s 3200 Series are heavy duty, low-maintenance conveyors. They are best suited for medium-to-large part handling in a variety of… Read more »

See Dorner’s Conveyor Transfers in Action

Dorner’s industry leading transfers are designed to efficiently move your product while preventing product loss. Whether you’re transferring in-line,… Read more »

Dorner Merge Conveyors

Dorner offers a variety of solutions for merging products in a processing line. We can merge 2, 3, 4 or… Read more »

New Service Videos Now Available – AquaGard 7350 Series

Do you have a new AquaGard 7350 Series Modular Belt Curve conveyor you need to install? Or do you need… Read more »

Custom Accumulation Systems

When you need to ensure a steady supply of product to a machine or to hold a supply of product… Read more »