Predictive maintenance for conveyors reduces unplanned downtime by using sensors and monitoring systems to detect problems before they cause complete… Read more »

Category: Conveyor Maintenance

3 Ways to Reduce Unplanned Downtime in Manufacturing

Downtime is an inevitable factor in manufacturing, whether it’s at planned intervals for line changeovers, or unplanned downtime due to… Read more »

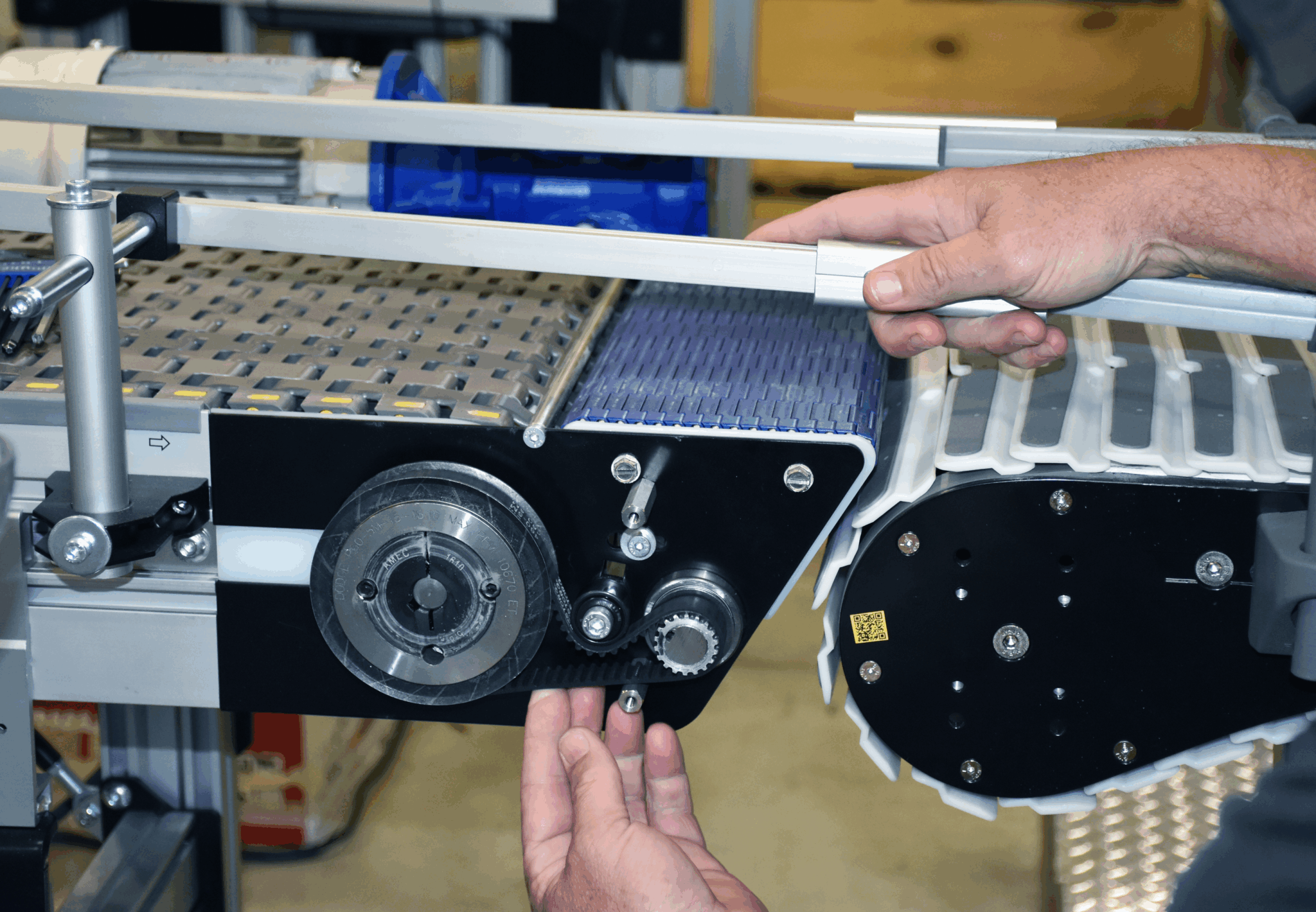

Reducing Production Obstacles with Replacement Parts

Customers often ask us for recommendations on what are the best replacement parts to keep on hand for their conveyor… Read more »

ERT Provides Simple Reconfiguration in the Field

To keep up with continuously changing demand, manufacturers are facing the pressure to improve their process while still developing… Read more »

Learn How to Service Your ERT250 Conveyor

ERT250 Conveyors Dorner’s ERT250 Conveyor is the latest advancement in pallet and tray handling conveyance. This new type of… Read more »

Dorner Quick Tips: Dorner Installation Videos

Installing Your Dorner Conveyor System You just received your Dorner Conveyor and it’s time to install. Included with your… Read more »

How to Service Your AquaGard 7350 Belted Conveyor

The AquaGard 7350 Series is Dorner’s go to conveyor for wipe down and low pressure wash-down sanitary applications. They… Read more »

Learn the Service Basics For Your 3200 Series Center Drive

Dorner’s 3200 Series are heavy duty, low-maintenance conveyors. They are best suited for medium-to-large part handling in a variety of… Read more »

Cleaning Tips for Industrial Conveyors

While customers are often familiar with cleaning and sanitizing stainless steel sanitary conveyors, which are built for daily wipe downs… Read more »

New Service Videos Now Available – AquaGard 7350 Series

Do you have a new AquaGard 7350 Series Modular Belt Curve conveyor you need to install? Or do you need… Read more »